Traysealer

Traysealer traysealers are tray sealers, the result of an in-depth study by our engineers. They are characterized by having a fast format change and a small size.

They are indicated to solve the main problems that exist in this type of packaging machines; optimizes OEE, solves production stoppages, improves maintenance, ensures efficiency…

Rarely is a technological solution called into question after its maturity. Nexes Traysealer is the result of in-depth study by our engineers to solve the common problems of all customers who use tray heat sealing technology on a day-to-day basis.

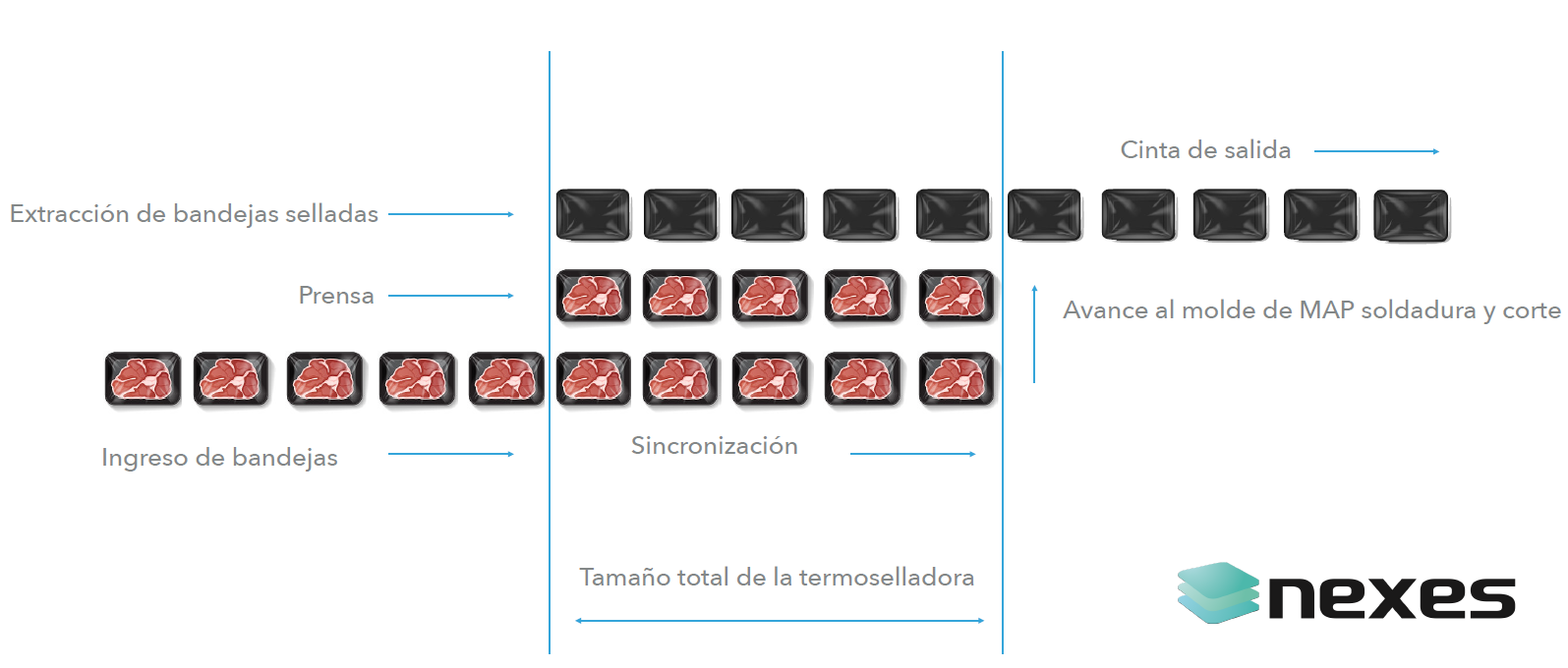

Certain solutions become the standard of the technique until they are improved. The online loading and demolding system of current traysealers compromises space and generates certain inconveniences that have never been solved.

Nexes Traysealer with its patented solutions, takes an innovative approach to solving persistent problems in heat sealing technology:

- Improve maintenance.

- Solve production stoppages.

- Ensures efficiency and consistency in tray sealing.

- It guarantees that no product is delivered with integrity failures.

- Optimize the OEE.

- Improve production per minute.

- Reduces the consumption of noble gases and oxygen.

- Avoid stoppages due to reel change, both the new one and the discarded remnant.

- Ensures that all trays have the same MAP level.

- Without torsion in the mold and loss of vacuum.

- Fits on every tray.

Each cavity is independent to ensure complete and repeatable control of cutting, pressing, sealing, Mapping and welding.

It facilitates cleaning, due to its hygienic construction and simplifies accessibility for operation and maintenance.

Simple operation.

Optimizes space, in the footprint of a conventional traysealer, Nexes can provide a traysealing solution with the same mold size and its equivalent production, in addition to 100% control of leaks and metal control (X-Ray) and weight.

Tray movement strokes are shorter, improving product management.

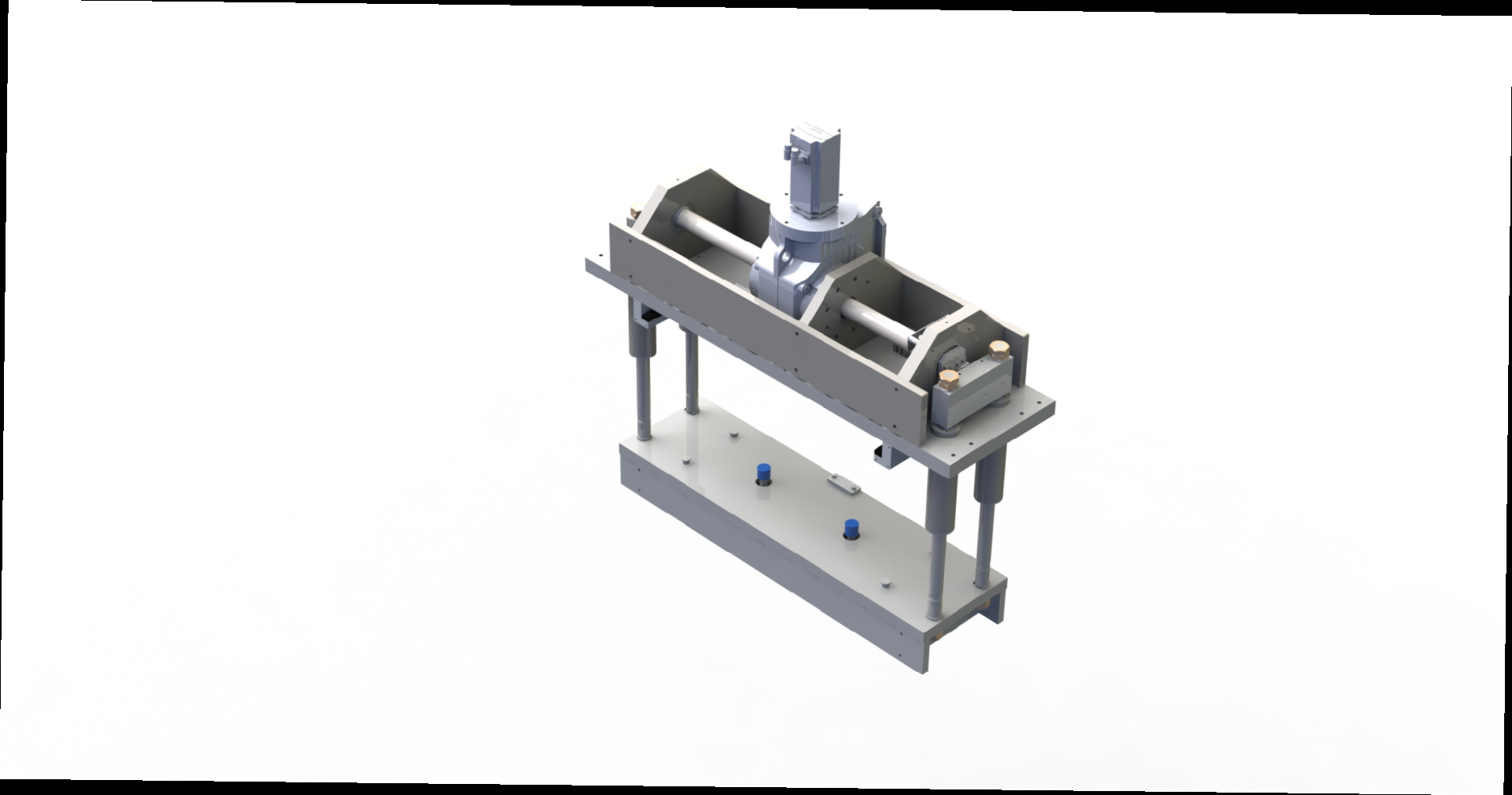

The Nexes Traysealer press has the mechanics on top, there is nothing below the mold table. A servo reducer allows precise movements, by giving the degrees of rotation to the axis that drives the eccentric that raises and lowers the table where the mold is anchored. This is supported by 4 guided columns, which allow all the mass to be in the mechanism and the efforts do not affect the chassis structure. Once the mold has been removed for the format change, the machine can be washed with pressurized water.

Our design has the following characteristics:

- Up to 8 tons of pressure.

- Perfectly balanced and robust, when accessing from the side the columns are very close together.

- Easy maintenance at man height.

- Hygienic, completely in stainless steel.

- Very fast and easy to program.

- Perfect parallelism.

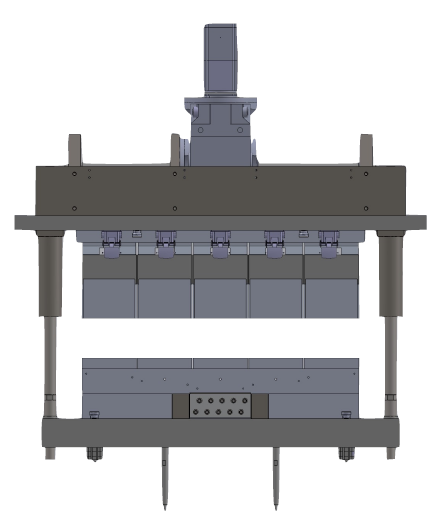

Each welding and cutting socket is mechanically independent.

The format mold of the Nexes machine differs from current heat-sealing machines in its construction quality, it has 4 guide columns and 8 springs for each of the lasts independently. Thanks to this, it guarantees that the 8 tons of pressure exerted are distributed evenly for each tray.

Quick format change. The entire mold or each of the upper components of the same can be extracted individually with the extractor carriage.

It adapts to possible tray errors and can continue working by canceling one or more alveoli.

Very robust, no flexing due to temperature, unbeatable welding quality.

It works perfectly with the new film materials and trays.

Facilitated maintenance without production stops.

Great ease of access and maintenance.

Nexes machines achieve MAP levels that are always repeatable and maintained during all production hours.

Because each cell has its own independent mould, the Traysealer has a vacuum hood for each tray, with its own individualized vacuum and gas injection quick connectors, enabling faster evacuation times and full control of gas consumption. . The set-up of the mold is very fast.

Improves the consumption of noble gases and oxygen.

All trays are the same, repeatability second to none.

No slipstreams or affectations by temperature.

Ease of adjustment, by being able to regulate the machine with a single mold and being able to equalize all of them, by program, once the parameters have been validated.

Sealed cavities, without vacuum losses.

Monitoring of each cycle and each cavity with downloadable protocol.

Benefits

Traysealer